- 您现在的位置:买卖IC网 > Sheet目录1063 > 10136-6000EC (3M)CONN MDR PLUG 36POS IDC GOLD

�� �

�

�

�6.�

�Locate� cutting� unit� stop� brackets� and� thumbscrew� (D� &� E�

�of� Fig.� 4).� Depending� on� size� of� assembly� choose�

�7.�

�8.�

�Push� platen� back� into� place� using� the� side� bar.�

�After� installing� the� stop� bracket,� position� the� armature�

�stop� bracket� accordingly.�

�(Black� for� 14-50� position� and� Silver� for� 68-100� position.)�

�Stop� brackets� are� installed� using� the� thumbscrew�

�(A� &� B� of� Fig.� 2).�

�of� the� press� back� in� an� upright� position.� Tighten� the�

�thumbscrew� (C� of� Fig.� 2)� to� hold� it� in� place.�

�9.� Located� at� the� back� of� the� press� is� a� silver,� dowel� shaped�

�shuttle� stop� (D� of� Fig.� 2).� Set� shuttle� stop� for� appropriate�

�connector� pin� count.�

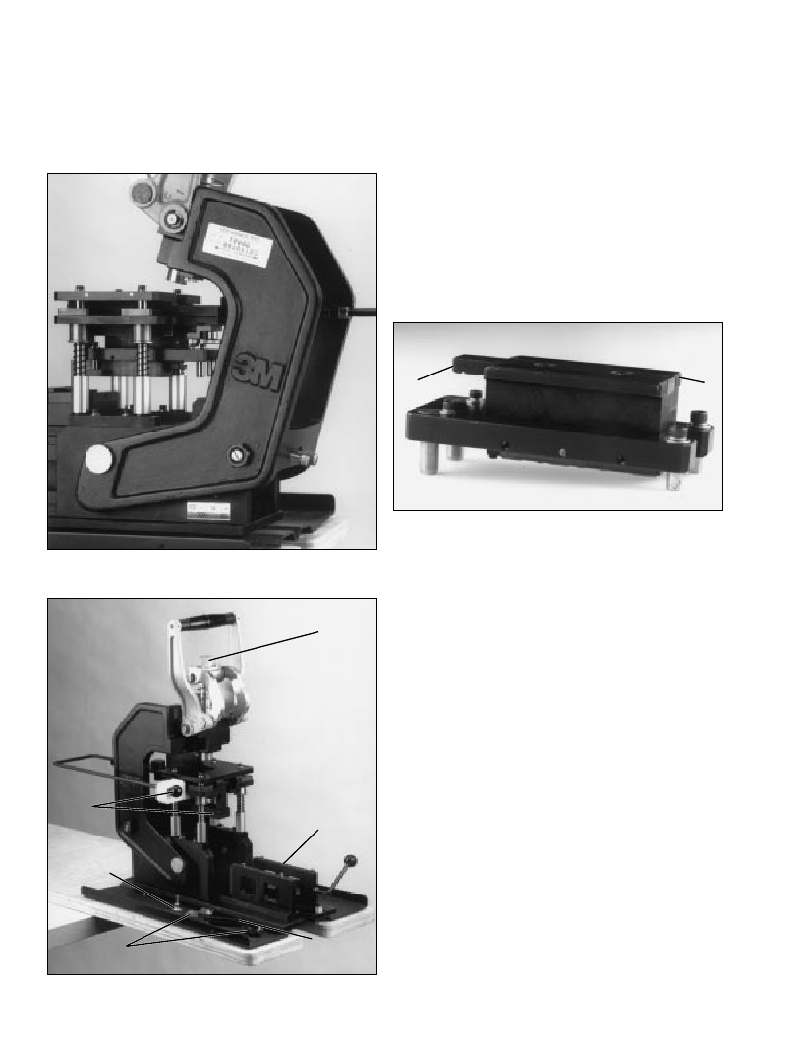

�10.� Locate� the� shuttle� block� (C� of� Fig.� 4)� and� install� fixture�

�unit� (Fig.� 14)� on� the� guide� pins.� Push� the� release� buttons�

�on� the� front� of� the� fixture� unit� to� open� the� grooved� plates.�

�11.� Locate� the� gauge� block� (F� of� Fig.� 4).� Height� adjustment�

�can� be� accomplished� by� placing� the� gauge� block,� narrow�

�side� down,� in� the� fixture� unit� between� the� two� grooved�

�plates.� Close� plates� manually� by� squeezing�

�them� together.�

�B�

�A�

�5�

�Figure� 5.� 10961� Cutting� Unit�

�Figure� 3.� Press� leaned� back�

�B.�

�Side� bar�

�A.�

�Height�

�adjustment�

�knob�

�3�

�12.� Push� shuttle,� with� fixture� unit� and� gauge� block,� away�

�from� the� operator� to� the� rear� of� the� press� until� it� stops.�

�13.� Pull� the� press� handle� down,� toward� the� operator,� until�

�the� platen� contacts� the� gauge� block.�

�DO� NOT� FORCE� HANDLE.�

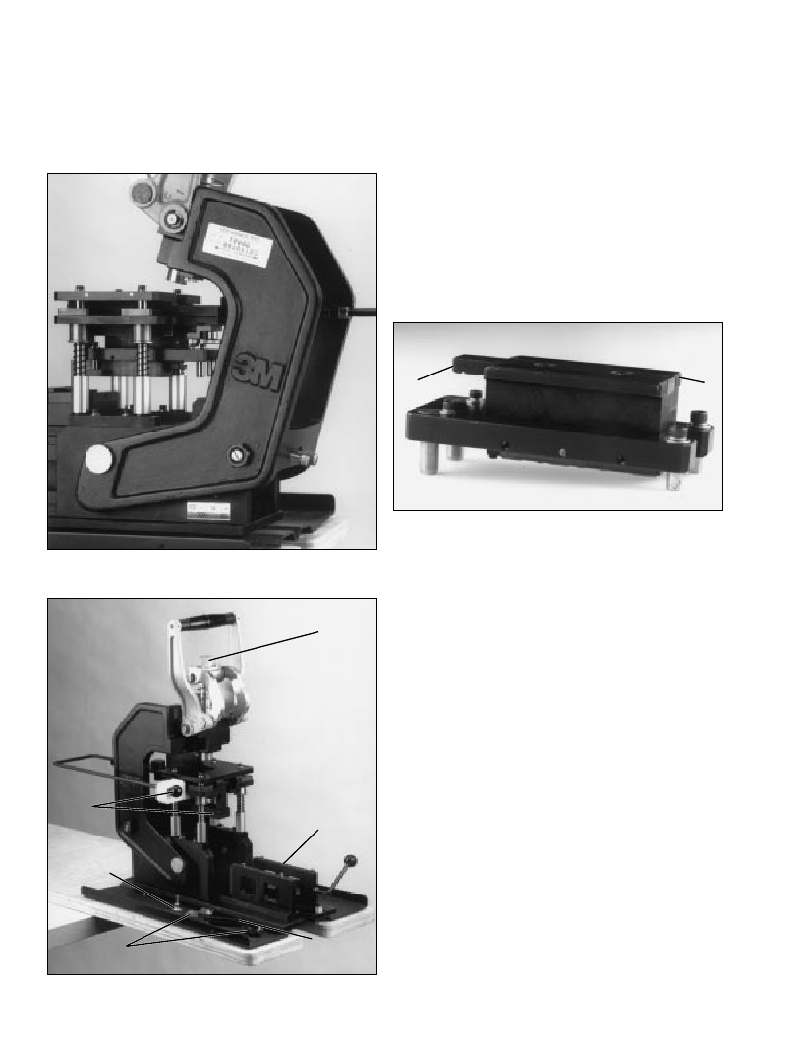

�14.� Adjust� the� silver� knob� at� the� top� of� the� press� (A� of� Fig.� 4)�

�by� hand� until� the� platen� lightly� contacts� the� gauge� block.�

�Lift� press� handle� up� and� adjust� the� silver� knob�

�approximately� another� one-half� turn� tighter.� Pull� handle�

�down� again.� It� should� lightly� lock� in� place� when� fully�

�depressed.� The� platen� should� apply� enough� pressure�

�on� the� gauge� block� and� shuttle� to� prevent� them� from�

�moving� when� trying� to� slide� them� out.�

�15.� Height� adjustment� should� be� checked� periodically.�

�Fixture� Unit� Adjustment�

�knob� &�

�platen�

�C.�

�Shuttle�

�block�

�Once� the� size� of� the� connector� to� be� assembled� has� been�

�determined� the� 10962� Fixture� Unit� requires� some� adjustments.�

�E.�

�Thumbscrew�

�D.�

�Stop� brackets�

�F.�

�Gauge� block�

�1.�

�2.�

�Select� the� correct� connector� stop� (14,� 20,� 26,� 36,� 40,� 50,�

�68,� 80� or� 100� position;� B� of� Fig.� 14)� for� your� application.�

�Locate� the� yolk� shaped� cover� plate� (A� of� Fig.� 14)� and�

�thumbscrew� at� the� top� of� the� fixture� unit.� Remove�

�and� set� aside.� Close� fixture� unit� grooved� plates� by�

�manually� squeezing� them� together.�

�4�

�Figure� 4.� 10960-2000� Hand� Press�

�2�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

10150-4CZ3PL

CONN MDR PLUG 50POS VERT T/H

10150-72E2PC

CONN MINI-D 50POS R/A PLUG

10150-8000EE

CONN PLUG 50 POS MINI-D

10168-6010EC

CONN MDR PLUG 68POS IDC 26AWG

101A0-4CZ3JL

CONN MINI-D 100POS VERT PLUG

101A0-900APL

CONN MDR PLUG 100POS VERT SLD

101A0-900AVC

CONN MINI-D 100POS EDGE PLUG

102-799-16

CONN PLUG 1.0/2.3 PUSH PULL

相关代理商/技术参数

10136-6000EL

功能描述:D-Sub微型D连接器 36P METAL FACE PLUG 28 AWG RoHS:否 制造商:3M Electronic Solutions Division 位置/触点数量:26 排数:2 安装风格:SMD/SMT 安装角:Right 端接类型:Solder 型式:Female

10136600-101LF

功能描述:VS2 5X6 RH SM 1S/G 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:1,500

10136600-102LF

功能描述:VS2 5X6 RH SM 2S/G 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:336

10136644-0311LF

功能描述:MINITEK PWR 4.2 REC HSG 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:1,000

10136644-0321LF

功能描述:MINITEK PWR 4.2 REC HSG 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:1,000

10136644-0322LF

功能描述:MINITEK PWR 4.2 REC HSG 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:1,000

10136644-0411LF

功能描述:MINITEK PWR 4.2 REC HSG 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:1,000

10136644-0421LF

功能描述:MINITEK PWR 4.2 REC HSG 制造商:amphenol fci 系列:* 零件状态:在售 标准包装:1,000